6 Reasons You Need Planer Blade Sharpening From Leitz Tooling:

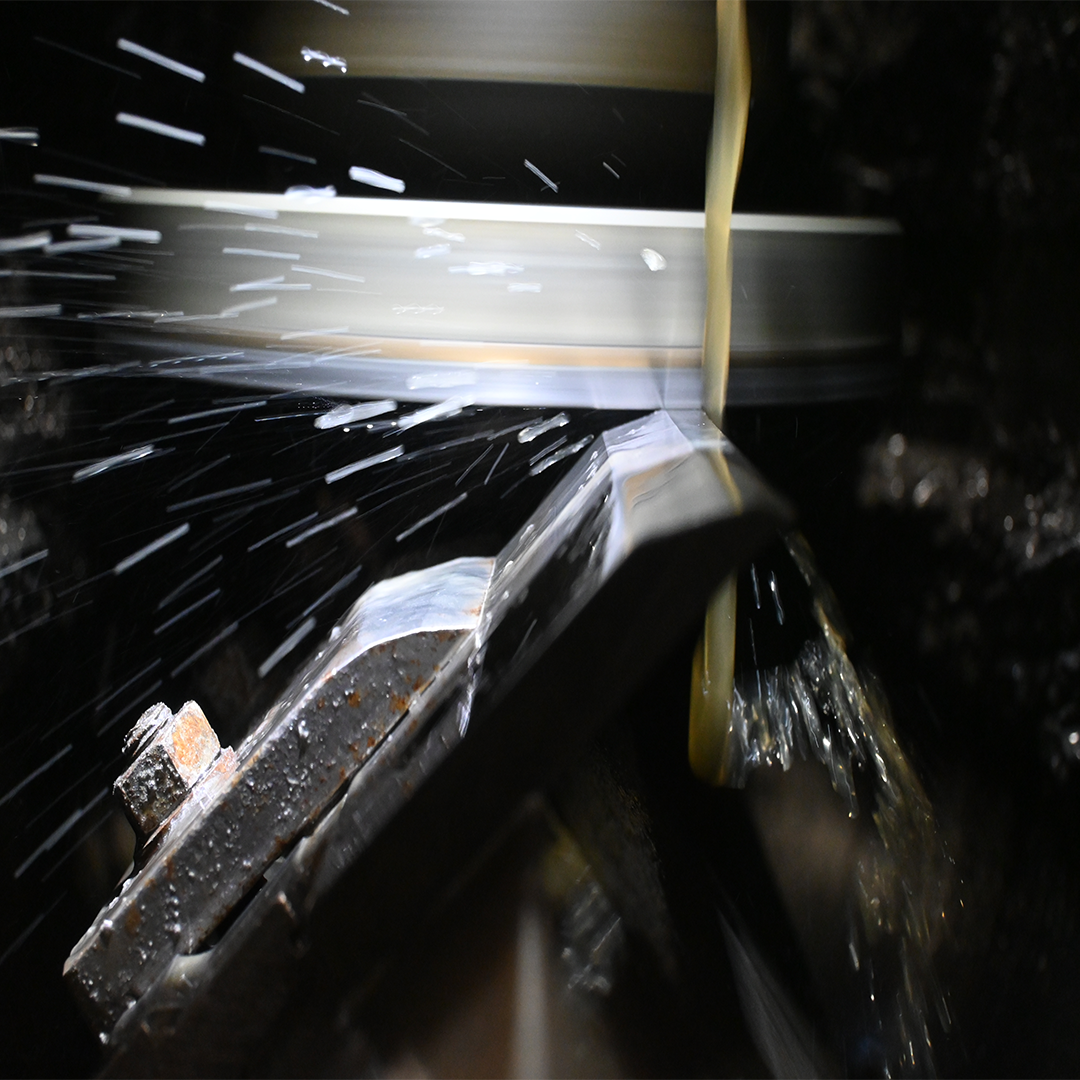

The performance of your thicknesser or planer directly depends on the quality of its cutting edges. Operating with dull blades leads to compromised material finish, inefficient workflow, and unnecessary wear on your valuable machinery. Investing in expert planer blade sharpening is a critical maintenance decision that ensures maximum productivity and the highest quality output.

Discover the definitive advantages of professional planer blade sharpening and how this service can immediately elevate the standard of work in your workshop.

Why Use Planer Blade Sharpening?

- Extended Tool Life.

- Improved Surface Finish.

- Conistent & Precision Cutting.

Your Benefits:

- Lower Blade Replacement Frequency.

- Reduced Rework.

- Less Material Wastage.

1) Planer Blade Sharpening Improves Your Accuracy:

Regular planer blade sharpening is essential for accurate and consistent planing. When your blades receive high-quality planer blade sharpening, they are restored to their precise factory cutting geometry. This guarantees that your planer removes exactly the amount of material you intend with every pass, delivering perfectly uniform stock thickness across the entire workpiece. This precision, achieved through professional planer blade sharpening, is non-negotiable for high-end woodworking. It also leads to reduced material wastage.

2) Improved Surface Finish With Planer Blade Sharpening:

Planer blade sharpening is essential for maintaining a high quality finish. As planer blades become dull or blunt due to machining and damage, their geometries can become misaligned causing the planer blades not to cut as intended. This results in chipping or tear out on the workpiece as well as inconsistent finish quality, leading to high costs from wastage and time costs of rectification. Frequent planer blade sharpening eliminates this challenge as it maintains your planer blades intended cutting geometries. Planer blade sharpening also allows the sharpener to remove any raised or damaged areas on the planer blade – allowing for smooth finishes.

3) Reliable and Consistent Cutting with Planer Blade Sharpening:

Dull planer blades are inherently unpredictable; they might cut fine on soft grain but struggle, gouge, or chatter when hitting a knot. Restoring the razor-sharp edge through routine planer blade sharpening ensures smooth, reliable performance every single time you feed timber or panel material through your machine. This predictability means you can trust your planer to deliver the same high-quality result from the first piece to the last. Investing in professional planer blade sharpening allows you to focus on the rest of your project instead of constantly compensating for poor blade performance. This also reduced rework and wasted material form inconsistent cutting.

4) Reduced Power Consumption and Machine Wear:

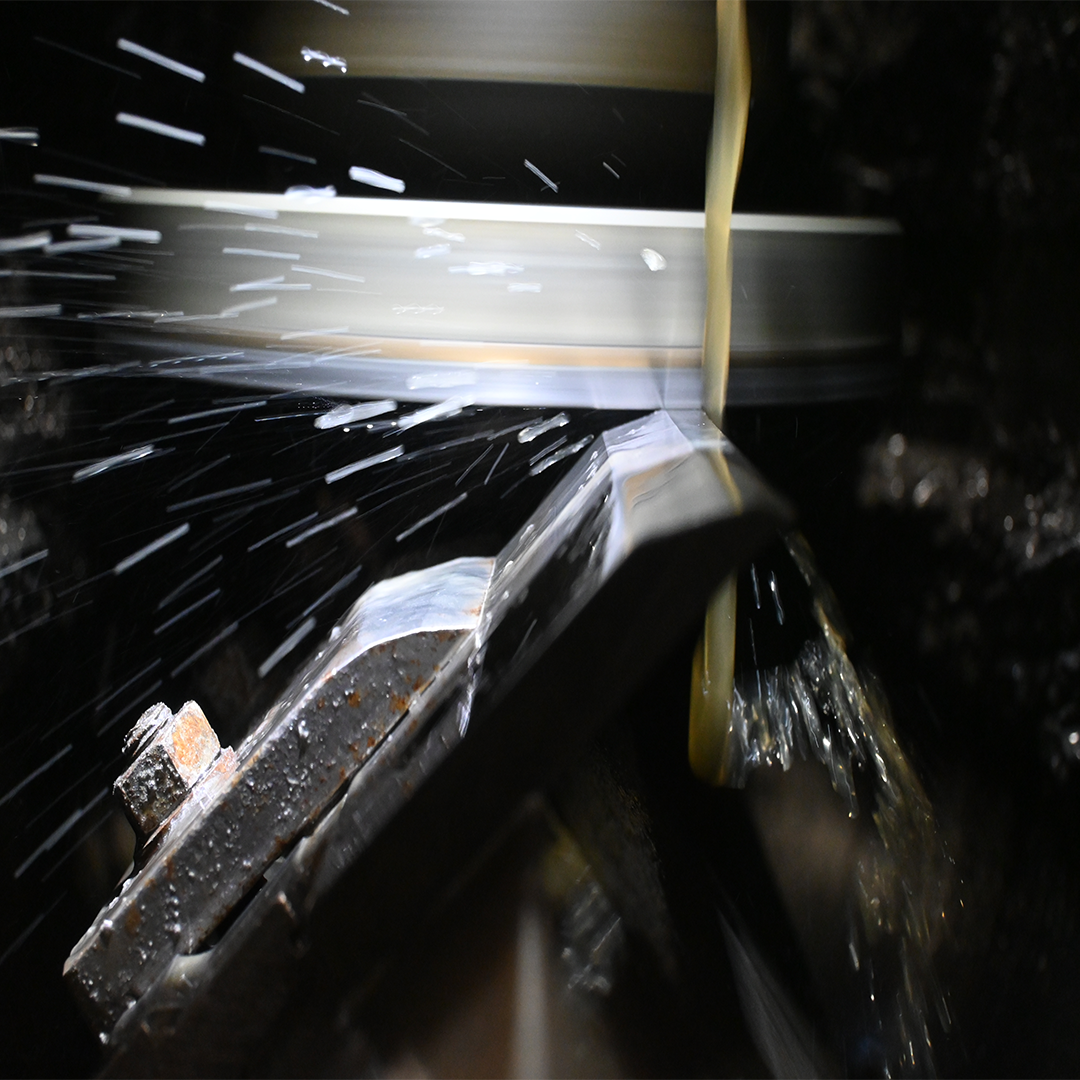

Often misunderstood, planer blade sharpening has massive impacts on the wear of your machinery and its motors. Blunt or damaged planer blades require significantly more power to be consumed when pushing through material. This means that planer blade sharpening can actually reduce the cost of manufacturing by lowering power consumption.

Additionally, planer blade sharpening also reduces machine and motor wear. Machinery parts and getting them, serviced is very expensive, especially for smaller companies. Unbalanced , blunt and low quality planer blades cause your machinery parts such as motors and spindles to wear at increased rates. Planer blade sharpening reduces this impact by creating smaller cutting forces when machining.

5) Extended Tool Life and Lower Tooling Costs With Planer Blade Sharpening:

As material and especially carbide costs have increased dramatically in recent years, planer blade sharpening has never been more important for tool economy. Professional planer blade sharpening extends your blade's life by allowing them to be restored to peak performance multiple times, Leitz can typically chieve five times or mor on each blade before needing a replacement cutter. This results in lower replacement costs thanks to extended tool life.

Planer blade sharpening also reduces the chance of chipping or damaging your tool. Because sharpener blades require less power and create less cutting forces, there is a heavily reduced chance of chipping or damaging your planer blade on a workpiece after sharpening. This reduced your replacement frequency and therefore your overall tooling costs.

6) Extended Tool Life and Lower Tooling Costs With Planer Blade Sharpening:

Although most planer blades are typically used on enclosed machinery , planer blade sharpening still has massive health and safety advantages that can be overlooked my machinists. Working with planer blades can be dangerous because they demand more force and are less predictable. Dull blades significantly increase the risk of kickback due to the uneven forces on the tool. Planer blade sharpening eliminates this risk by evening out the forces at play and spreading force across the entire blade geometry.

Contact Leitz Tooling For High-Quality Planer Blade Sharpening Today: