Professional Knife Sharpening From Leitz Tooling

A Reliable & Repeatable Knife Sharpening Service

Professional knife sharpening services are an essential yet often overlooked part of the manufacturing industry, as companies look to extend tool life, reduce costs and improve their product quality through the use of knife sharpening services like Leitz. But with an abundance of sharpening services on the market, what should you look for from a sharpening service? And how does Leitz tooling set itself apart through its professional knife sharpening services?

The Importance of professional knife sharpening for manufacturing industries:

In the fast-paced world of manufacturing, efficiency and precision are paramount. This is where professional knife sharpening and blade sharpening come into play. While it may seem like a minor detail, keeping blades sharp offers a significant competitive advantage across various manufacturing sectors.

Sharpened blades carve through materials with clean precision, minimising wasted material and maximizing output. This translates to a faster production line and a higher volume of finished goods. But the benefits extend beyond mere speed. Sharp blades produce cleaner, more controlled cuts, reducing material waste and elevating the overall quality of the final product – a critical factor in industries like joinery, furniture production, structural timber or general woodworking.

Professional sharpening extends the lifespan of blades, minimizing the amount of downtime needed for repairs and replacements. Dull blades are more susceptible to breaking or bending, leading to unexpected production delays and the need for new blades. Regular sharpening ensures blades remain operational for longer, keeping your production line running smoothly.

Safety is another area where sharp blades shine. The increased effort required to use dull blades raises the risk of worker injuries from slips or lost control. Sharp blades offer greater precision and control, reducing the likelihood of accidents and keeping your workforce safe.

The cost of professional sharpening may seem like a hurdle, but the long-term cost benefits outweigh the initial investment. Reduced material waste, fewer blade replacements, and increased efficiency translate to significant cost savings over time and it can potentially help lower production costs.

Professional Knife Sharpening from Leitz, a reliable and repeatable service.

For over 150 years, Leitz Tooling has been a leading force in industrial knife sharpening and blade sharpening globally. Keenly aware of the profound impact these services have on our customers’ success, Leitz distinguishes itself through a commitment to exceptional quality, advanced technology, and a deep understanding of diverse blade types.

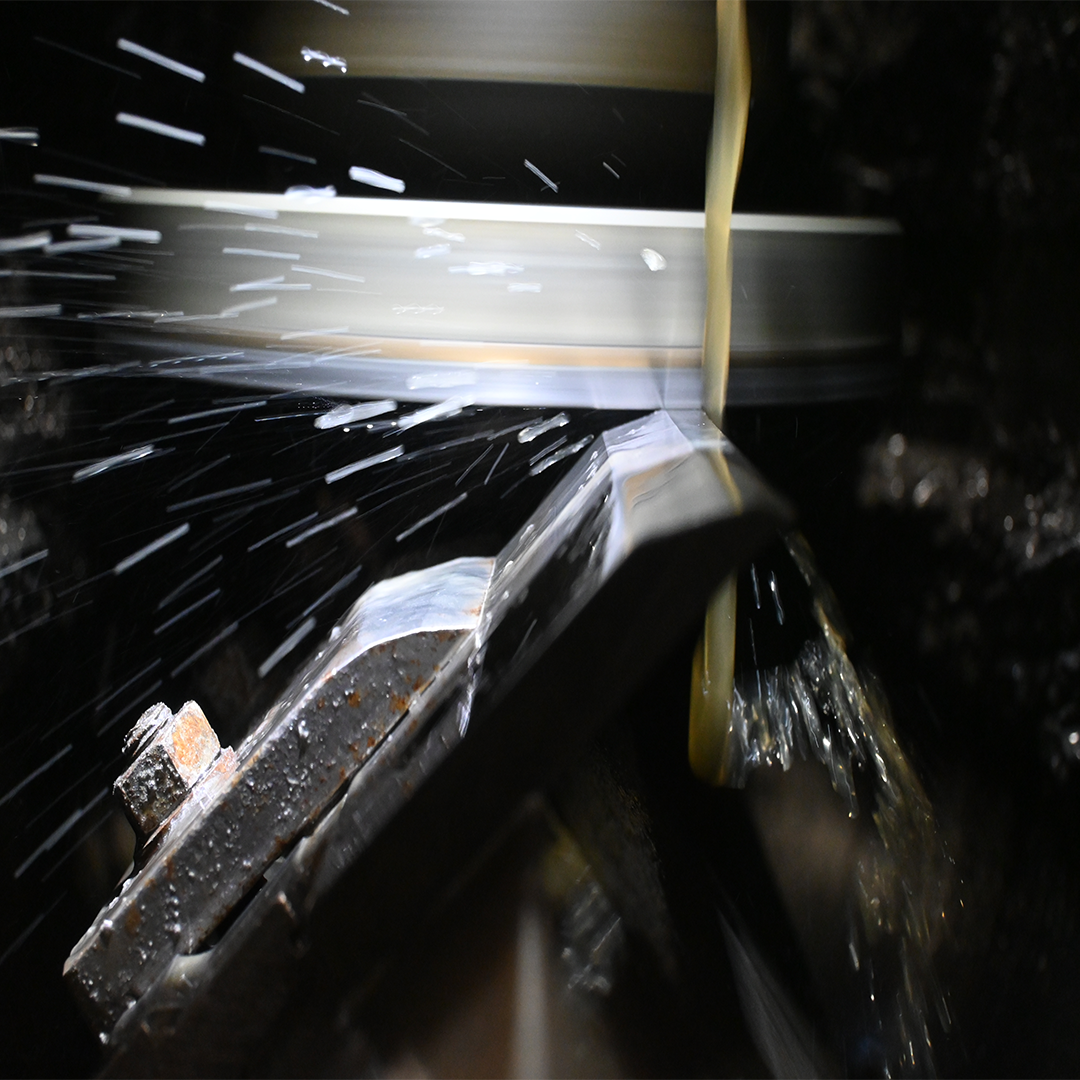

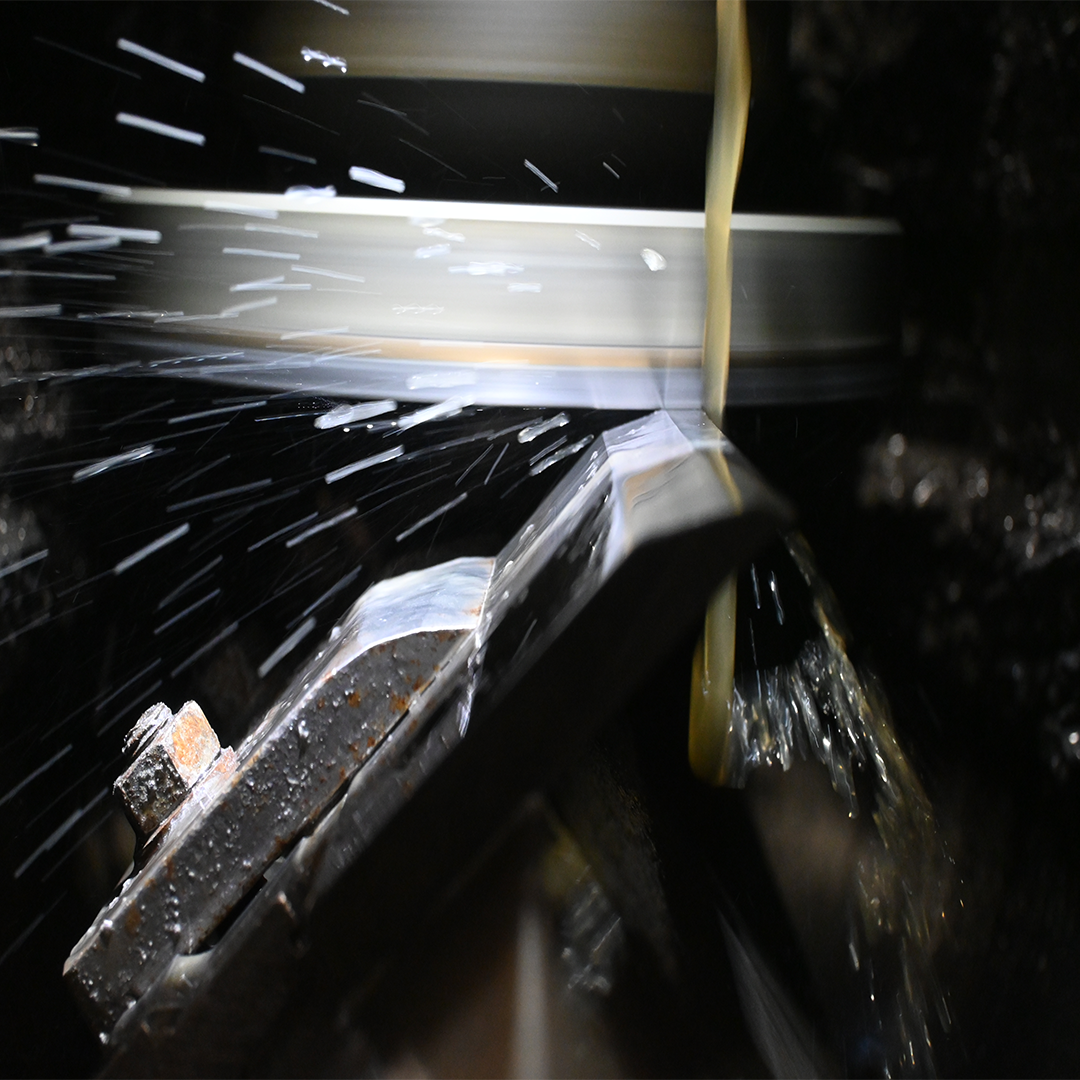

Leitz leverages cutting-edge machinery to guarantee precise and consistent sharpening across all services. Our commitment to innovation extends to the development of our own patented grinding wheels specifically designed for optimal sharpening of carbide knives – a testament to our dedication to catering to the specific needs of each blade or tool type. For diamond knife sharpening, Leitz boasts a team of specialists in diamond erosion, offering a comprehensive sharpening solution regardless of the cutting material.

Leitz has transformed knife sharpening and blade sharpening to a scientific art form. We have implemented a standardised sharpening processes across all our global service centres, ensuring consistent, micron-level accuracy, regardless of location. This meticulous approach translates to blades that deliver exceptional performance on the production floor. Furthermore, Leitz uses advanced measuring tools and visual equipment to ensure the sharpened blade has had all the wear removed from the cutting edge and creates a consistent and sharp cut.

Leitz's commitment goes beyond simply sharpening knives. Time and time again, we leverage the data gathered from sharpening activities and tool management to provide invaluable insights to our customers. This data can be used to recommend adjustments to feed speeds or tool paths within the machining process, maximizing efficiency and ensuring your sharpened knives perform at their absolute best. By partnering with Leitz, you gain access to a wealth of knowledge and expertise that extends far beyond the sharpening service itself.

Leitz Tooling is more than just a knife sharpening and blade sharpening service – we are a trusted partner dedicated to keeping your manufacturing operation running at its sharpest edge. Our unwavering commitment to precision, innovation, and comprehensive knife sharpening and tool management solutions ensure that you receive the highest quality knife sharpening available, along with valuable insights to optimize your entire machining process. Choose Leitz today to experience the difference that exceptional sharpening can have on your productivity.

Diamond Knife Sharpening Specialists:

Diamond knives, with their exceptional hardness and cutting ability, present a unique challenge when it comes to knife sharpening. Traditional methods simply won't do, Diamond knife sharpening demands a specialised approach to maintain peak performance and extend blade life.

The benefits of diamond tooling for manufacturers are clear. Diamond tooling allows for a superior level of sharpness and durability compared to traditional tooling. This translates to cleaner, more precise cuts, minimising material waste and enhancing the overall finish quality of the product.

Diamond knife sharpening is an intricate process that Leitz group has mastered over our 150 years of experience, Leitz can sharpen your diamond tools and knives back into like new quality and within microns of accuracy. Our diamond knife sharpening service helps manufacturers to maintain control over finish quality when machining denser and difficult materials.

The Benefits of Knife Sharpening For Regular Preventative Maintenance:

Utilising knife sharpening services from well rated and trusted service providers such as Leitz Tooling proactively addresses potential issues, manufacturers can significantly reduce the risk of unexpected downtime with knife sharpening. This is because regular preventative maintenance extends the tool life of the knives and can help machinists keep informed about the expected end of life of their tooling. Services like tool management from Leitz helps machinists avoid unexpected end of life tools – which can cause significant bottlenecks in production and lead to wasted capacity.

As knives are used to machine timber any other material, they are damaged. If not maintained, this can lead to uneven surfaces of planer knives or poor finishes on grooving or profile knives as well as reduced accuracy. Therefore regular maintenance can lead to a consistent standard of finish quality. Potentially resulting in less need for sanding, site rectification or rework.

Contact Leitz for professional knife and blade sharpening services near you:

If you are looking for high quality knife sharpening or blade sharpening services, contact your local Leitz team today. With 8 service centre across the UK, our sharpening team can cater to your needs nationwide. We offer flexible delivery options through courier or van delivery. If you would like to learn more about our tool management, you can do so here.