Permadoor embraces solutions from Leitz Tooling

Since it was established in 1989, Permadoor, based near Worcester, has produced over a million doors. As the creator of the first low maintenance composite door in the UK, Permadoor’s extensive experience in GRP door production is undeniable, but when current sales demand appeared to require the introduction of a working night shift, it took teamwork with Leitz Tooling for Permadoor to find an alternative solution.

Permadoor has a policy of continuous improvement. It makes significant investments in technology, CNC machining centres, and in its employees with ongoing training programmes. Continuous improvement also means evaluating manufacturing efficiency and productivity.

David Welsby, Permadoor’s engineering and maintenance manager explains, “About two years ago we knew we had an issue with our previous tooling supplier. There was simply no back-up when we needed it, no-one was taking any responsibility and supposedly reasonably priced tooling was working out to be very expensive. A change in tooling supplier is not a decision made lightly for any size of company, but we put through serious volumes of product, and we could not afford for our high standards and quality to be compromised in any way.”

At the time, the company’s sales demand was leading to the set-up and considerable cost of a premium shift pattern five days a week. Finding a proactive tooling partner in Leitz, together they completely reviewed how Permadoor was using tooling, what issues and problems there were, what tooling was breaking and why?

Cycle times for machining was the major constraint. After much analysis and consideration, the solution of alternative cutters provided savings in cycle times within a range of between 100-150%, doubling the company’s CNC machines’ capacity overnight.

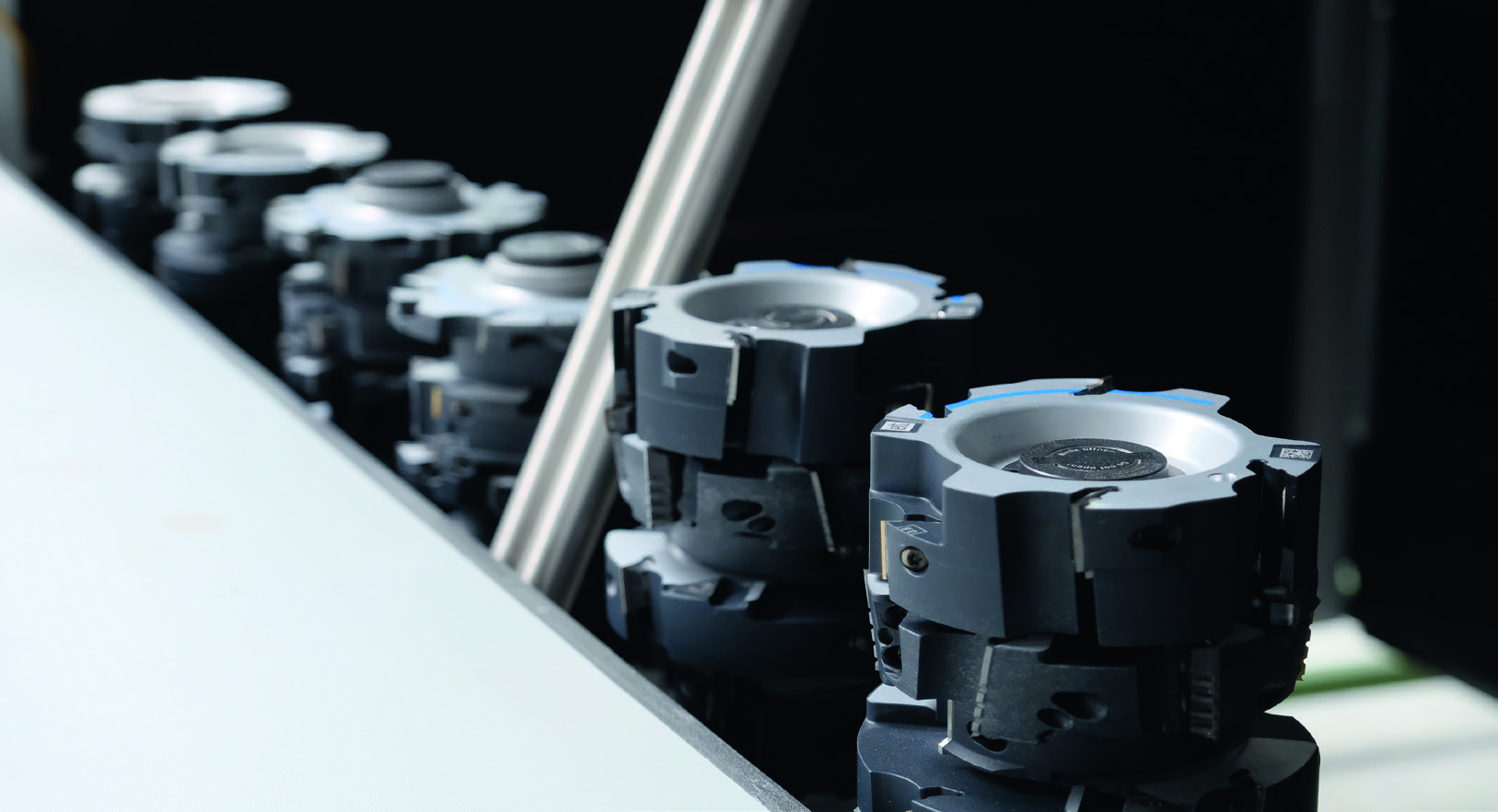

For the CNCs, Permadoor now uses a combination of Leitz Tooling’s spirals, diamond, Marathon and Profilcut tools.

Now seeing much greater efficiencies and tooling life expectancy, the drastically reduced cycle time enabled the daily production requirements to be manufactured in a single shift. In discussion with Leitz, Permadoor general manager Mark White identified that the entire night shift — previously necessary to meet demand — could now be reallocated, avoiding the company costs of in excess of £400,000.

“Additional operator training has proved a vital part of the service we receive from Leitz,” continued David Welsby. “It wasn’t just the tooling. With the production knowledge from the Leitz team we saved a further £25,000 in ancillary equipment such as pod replacement.

“These operator training seminars from Leitz Tooling make a huge difference in the knowledge of our workforce. They are fully on board and interested in the process. Our staff are valued team members who work with the company, not just for the company,” said David.

“For example, the machines were not being run to their true potential,” he continued. “If something sounded wrong, the general assumption was to run it slow. Leitz suggested optimising the speed and feed rate, which was a four-fold increase. Our response was ‘don’t be stupid’. The fact is, we were going far too slow for the job we were doing. We ran them to Leitz’s recommended speed anyway, and it cut beautifully. We are changing the cutters more regularly and in doing so are getting more durability from the tools. It might sound counterintuitive, but Leitz quality maintenance and service on the tools means we keep our product quality high and tooling costs down.”

Working with Leitz, the actual cost of the tooling for Permadoor has dropped by 45%. “If you just look at the finances of it, the tooling from Leitz can look more expensive, but the package is worth it, and the efficiencies and savings are there to be had without any doubt,” said David. “Leitz’s prices are actually not that much more than others, but there is no like-for-like comparison. Leitz’s tooling gives us a superior product, faster, more efficiently and with far less waste. The savings, and Leitz’s support, is massive.”

The level of scrap doors through cutter failure was also a priority in associated skip hire and landfill costs. But after the introduction of correct programming parameters, machine speeds and cutters with guidance from Leitz, the scrap from manufacturing reduced, with a visible and financial upside of circa £100,000.

David said, “Taking time to inform and share this knowledge with the operators is so important. Everyone takes pride in their work, but it makes an even greater difference when your team understands the huge positive impact of doing things correctly. Leitz provides the whole package including regular review meetings. Our general manager is more than happy; he is amazed by the quality, efficiency and financial gains Permadoor has enjoyed since working with Leitz for very little investment.”

Managing director Leitz UK, Simon Liddell, commented, “We are very proud of the Leitz team. This is a typical example of how we apply ourselves in the marketplace to assist companies across the spectrum. This goes towards achieving a major objective of ours which, amongst others, is to improve customer efficiency and subsequent profitability to help them grow in very competitive market conditions. We thank Mark White, David Welsby and the Permadoor team for allowing Leitz to work with them to mutual benefit.”

Leitz Tooling:

Permadoor: